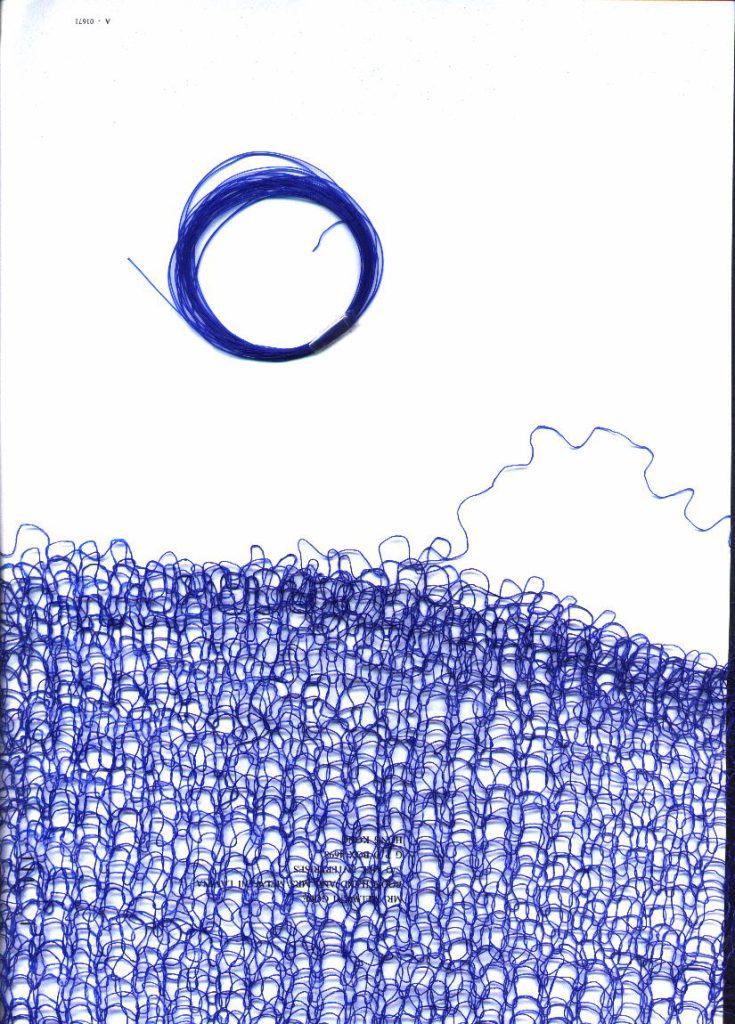

KNITTED MESH STOCKING

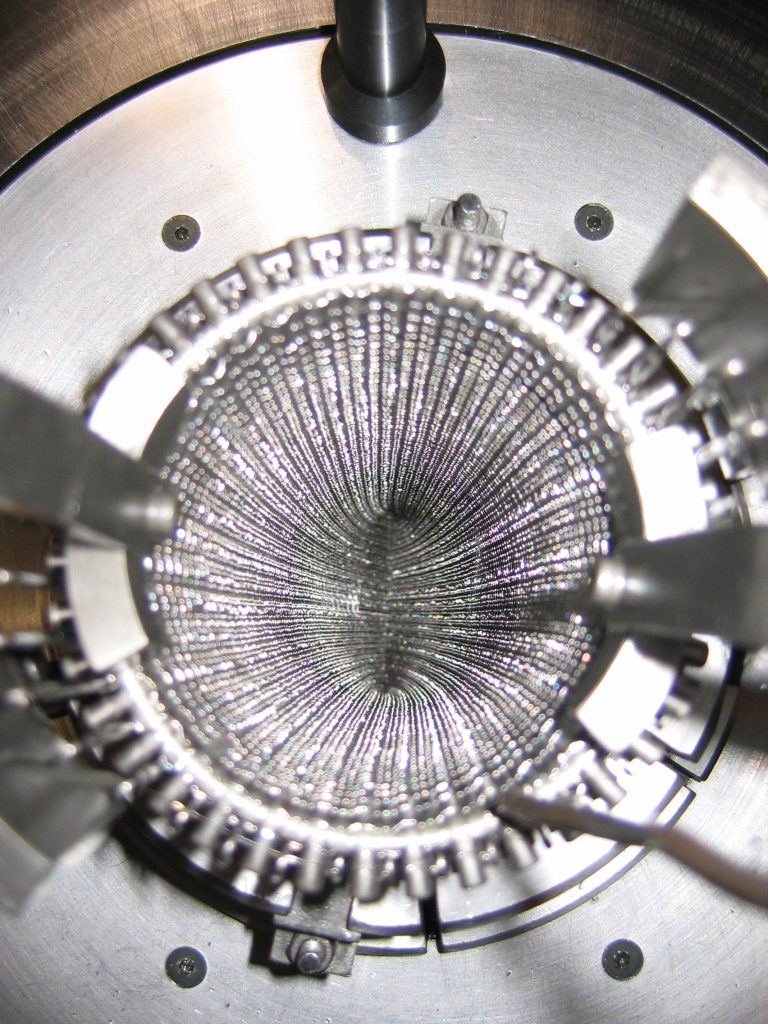

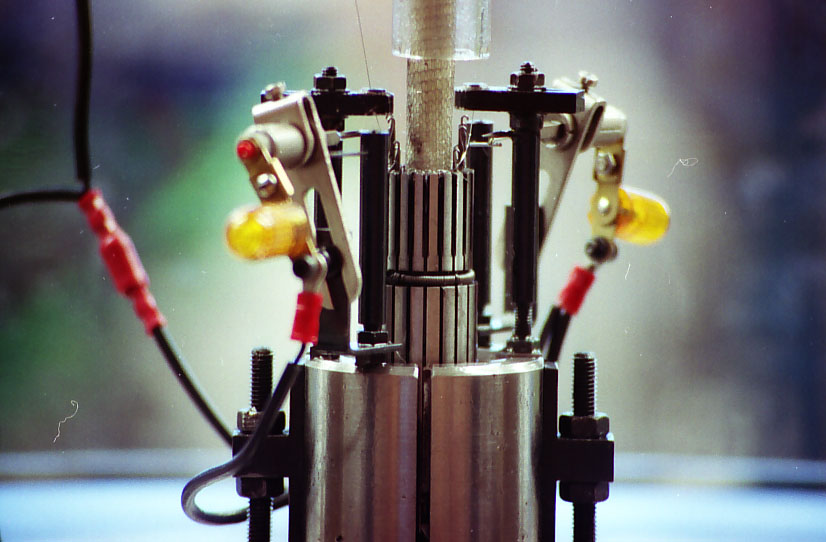

Wire Mesh Industries manufactures knitted mesh stocking on site from fine wire in an infinite range of stocking types, wire diameters, materials, mesh apertures, roll widths and more. The knitted mesh stocking is made using state of the art technology combined with highly skilled technical staff and the best of global materials to ensure world class competitiveness and quality across its knitted mesh product range. Knitted mesh stocking is made from asymmetric teardrop shapes loops and is strong and yet flexible to suit a variety of predominantly industrial applications.

Knitted mesh is made from metal or non-metal wires or a combination of metal and non-metal wires in a structure of continuous interlocking asymmetrical loops. The mesh is predominantly made in tubular form much like the socks on your feet and is typically made in continuous rolls. Anything that can be drawn into a filament can be knitted – Wire Mesh Industries knits with all forms of stainless steel, monels, hastelloys, incoloys, mild steel, duplex stainless steels, copper and more as well as non-metals such as HDPE, PTFE, fiberglass and more. Stocking widths run from as little as 10 mm flat width to more than 800 mm flat width and wire diameters from as small as 0.1 mm to bigger than 0.4 mm diameter.

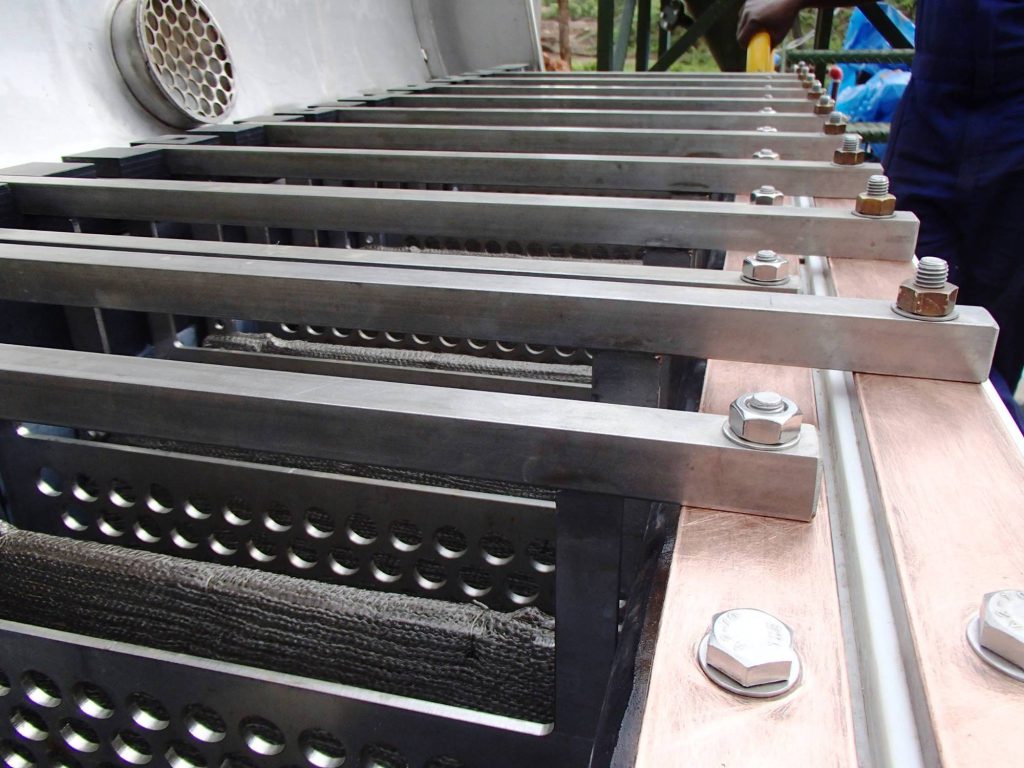

The unique configuration of knitted mesh makes it able to be manipulated into different forms to suit different applications. When corrugated and layered the knitted mesh presents an excellent surface area to volume ratio for use in products such as mist eliminators and other filters, when knitted with multiple fine wires under every needle the knitted mesh can be used to manufacture flexible yet strong blanket coverings for the insulation market and when compressed the flexibility and resilience of the knitted mesh can be used to make automotive seals and gaskets such as catalytic convertor seals.

The most common uses for knitted mesh stocking are in the manufacture of knitted mesh mist eliminators [filters], the manufacture of automotive components, the protection of insulation blankets from abrasive damage and the manufacture of cathodes for metal recovery in electrowinning cells. The ability to mix or change wire diameters, apertures, the corrugations or crimps in the knitted mesh, the layering and number of layers of knitted mesh, the material of the knitted mesh and more means the scope of applications for the use of knitted mesh are almost without end.